- Home

- Dehydration / Iqf Section

Dehydration / Iqf Section

DEHYDRATION / IQF SECTION

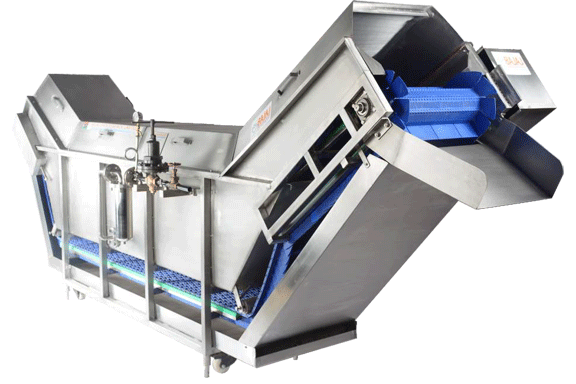

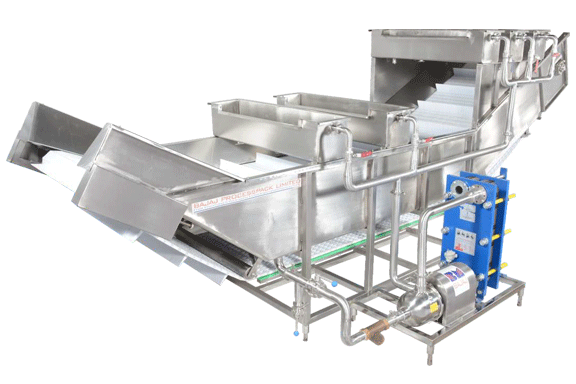

Suitable for Continuous pre Boiling / blanching of fruits and vegetables for softening / enzymatic treatment to facilitate destoning / pulping / dehydration / IQF Process.

Incorporates Conveyor type design to carry and convey the product thru the hot water to attain the requisite blanching temperature / time.

Available in capacities from 500-5000 kg/Hr

Suitable for continuous cooling of cut vegetable after blanching process before IQF / dehydration.

Incorporates belt type design to convey the products through cold/chilled water to ensure the product achieves ambient/chilled temperature before further processing.

Available in capacity from 500-5000 kg/hr.

Suitable for continuous pre-boiling/blanching of fruits/vegetables for softening/enzyme treatment to facilitate destoning/pulping of the same. Incorporates SS spiral screw which carries the product through the blanching tank. Available in steam jacketed/water immersion design with accurate temperature control.

Available in capacities from 500-5000 kg/hr.

Suitable to impregnate sugar syrup into cut / sliced / diced fruits under vacuum conditions. This enables the fruit to soak sugar syrup and improves

dehydration process and the taste of the finished

product.

Available in 200-2000 kg/batch product holding capacity.

Suitable for de-podding of peas from pea pods for

further processing into frozen / IQF products.

Available in capacities from 2-6 MT infeed per hour.

Suitable for dehydration / drying of various fruits/vegetables like ginger / garlic / onion / carrot / beans / leafy vegetables etc.

The Belt Dryer utilizes hot air to transfer heat and remove moisture from the product as it moves through

multiple temperature zones on the conveyor belt.

The hot air is created through hot air generator / furnance (solid fuel / oil based) and is blown inside the dryer through high pressure fans through variable fan speed / recirculation system.

The belt dryer can be customized to match different products according to their initial / final moisture levels and input/output capacity through variable air velocity/temperature and belt speed.

The dryer can be offered in various lengths from 3-20 mtrs with single / double / 3-tier designs to suit different capacities and products .

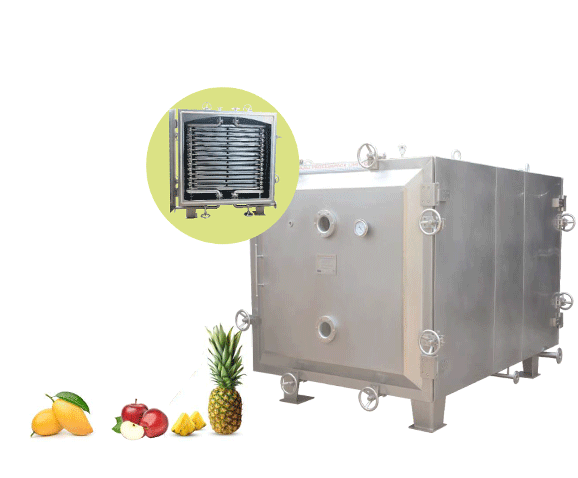

Suitable to dry various fruits and vegetables. The equipment utilizes low temperature drying under vacuum conditions which results in excellent quality dried product without loss of color, nutritional value or taste.

The dehydrator uses steam as the heating medium to dissipate heat evenly in the shelves. The products are spread out in perforated trays and placed on steam heated shelves. The chamber is vacuumized and the product is dried by indirect heat at low temperature.

Available in 4,12, 24, 48 and 96 trays capacity models with optional MS or SS outer body.